Blog

- Home

- /

- Blog

How to Choose the Best Textile Processing Chemicals for Your Needs

Choosing the right textile processing chemicals is crucial for manufacturers who aim to enhance the quality and sustainability of their textile products. With a wide array of available chemicals designed for various applications, from dyeing to finishing, understanding their functionalities and compatibility with specific fabrics is vital. The right selection can not only improve the performance of textiles but also influence the overall production process, environmental impact, and compliance with industry standards.

When considering which textile processing chemicals to use, it is essential to evaluate factors such as the type of fibers being processed, desired end properties of the finished fabrics, and any specific regulatory requirements that must be met. Additionally, the ecological impact of these chemicals should not be overlooked, as sustainable practices are increasingly becoming a priority for both manufacturers and consumers alike. Therefore, a thorough understanding of your operational needs and available chemical options will empower you to make informed decisions that enhance not only product quality but also your brand’s reputation in the competitive textile market. This article will guide you through the key considerations to help you choose the best textile processing chemicals tailored to your specific requirements.

Understanding the Types of Textile Processing Chemicals Available

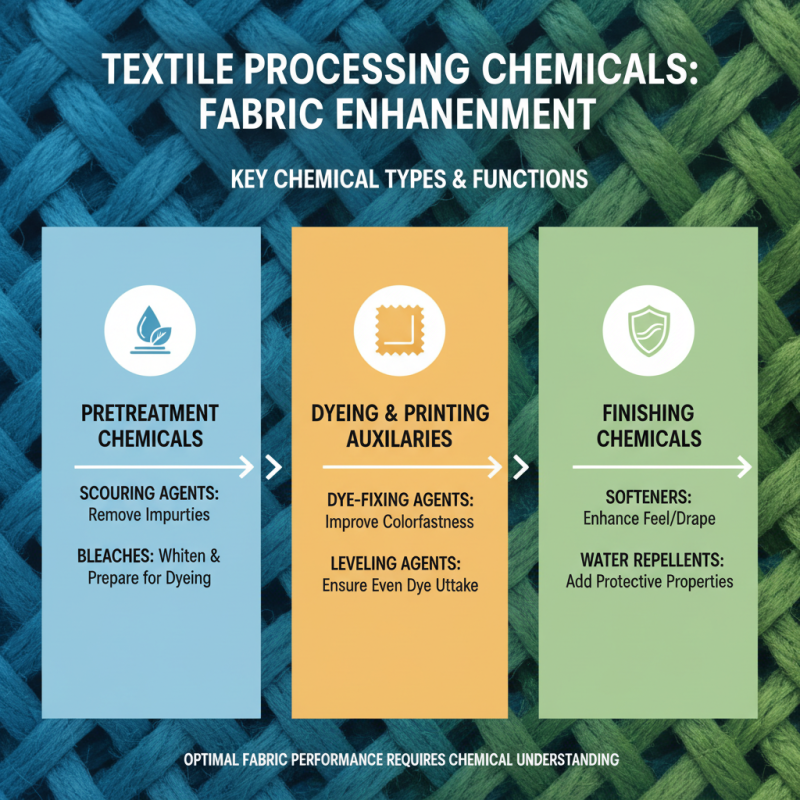

Textile processing chemicals play a vital role in enhancing the quality and performance of fabrics. These chemicals can be broadly categorized into several types, each serving distinct purposes during the textile processing stages. For instance, pretreatment chemicals, such as scouring agents and bleaches, are used to prepare the fabric for dyeing and finishing by removing impurities and ensuring better dye uptake. Understanding these foundational chemicals is essential for achieving optimal results in textile production.

Dyeing chemicals represent another critical category, encompassing various dyes and fixation agents that impart color to fabrics. The selection of dyeing chemicals involves considering factors like color fastness, environmental impact, and compatibility with different fabrics. Lastly, finishing agents, which include softeners, water repellents, and flame retardants, are utilized to enhance the textiles' functional properties and overall feel. By recognizing the diverse types of textile processing chemicals available, manufacturers can make informed decisions that align with their production goals and sustainability practices.

Identifying Your Specific Textile Processing Needs

Identifying your specific textile processing needs is crucial for selecting the most effective chemicals for your operations. A thorough assessment of your production processes, including dyeing, printing, and finishing, will help determine the type of chemicals required. For instance, if your facility focuses on high-temperature dyeing, you may need specialized dyeing auxiliaries that not only enhance color yield but also improve overall fabric quality. According to a recent report by Mordor Intelligence, the global textile chemicals market is expected to grow at a CAGR of approximately 3.5% from 2021 to 2026, signaling a rising demand for tailored solutions that cater to specific processing requirements.

Moreover, environmental considerations must play a significant role in your decision-making. With the increasing regulatory focus on sustainability, it’s essential to select chemicals that align with eco-friendly practices without compromising on performance. The Global Sustainability Report indicates that a significant portion of textile manufacturers (over 70%) are prioritizing sustainable chemical usage, which not only conforms to regulations but can also enhance market competitiveness. By evaluating your specific processing needs in tandem with sustainability goals, you can ensure that the chemicals you choose will not only meet current demands but also support long-term operational viability.

This bar chart illustrates the frequency of use for different textile processing chemicals based on industry needs. It highlights which chemicals are most commonly used and can help to identify specific requirements for textile processing.

Evaluating the Effectiveness and Safety of Chemicals

When selecting textile processing chemicals, evaluating their effectiveness and safety is crucial. Effectiveness can often be determined by examining the specific properties of the chemicals in relation to the intended application. For instance, some chemicals may be designed to enhance dye uptake, improve fabric durability, or provide water repellency. Understanding the interaction between these chemicals and the fibers used in production is essential for achieving desired outcomes, such as vibrant colors or prolonged fabric lifespan. Conducting tests and trials on sample materials can provide valuable insights into how well a chemical performs in real-world conditions.

Safety considerations are equally important when choosing textile chemicals. A comprehensive safety assessment should include an evaluation of potential health risks associated with chemical exposure during processing. Material Safety Data Sheets (MSDS) should always be consulted to understand the hazards, handling procedures, and first aid measures related to the chemicals being used. Additionally, regulatory compliance with local and international standards is necessary to ensure that the chemicals do not pose environmental threats or harm workers’ health. Embracing alternatives, such as biodegradable or less toxic options, can also contribute to safer processing practices and align with sustainability goals.

Considering Environmental Impact and Regulations

When selecting textile processing chemicals, the environmental impact and regulatory compliance should be at the forefront of your decision-making process. Understanding the chemical components and their potential hazards is crucial. Many chemicals used in textile processing can lead to harmful emissions or waste products, adversely affecting air quality and water sources. Thus, it is essential to review both local and international regulations that govern the use of these substances. Compliance not only protects the environment but also ensures that your operations remain economically viable by avoiding potential fines and legal challenges.

**Tips:** Always look for eco-friendly certifications and seek products with lower VOC emissions. Conduct a lifecycle assessment to evaluate the environmental impact of chemicals from production to disposal. Engaging with suppliers who prioritize sustainability can provide additional insights and support for your choices.

Furthermore, consider the shift towards biodegradable and non-toxic alternatives. The textile industry is progressively adopting greener practices, and by choosing formulations that are less harmful, you contribute to a more sustainable future. Always stay updated on the latest regulations and industry standards to make informed choices.

**Tips:** Utilize resources such as industry journals and regulatory websites to keep abreast of developments. Joining professional networks can also provide shared knowledge and tools to help evaluate chemical safety and sustainability.

Choosing Reliable Suppliers for Textile Processing Chemicals

When selecting suppliers for textile processing chemicals, it is crucial to prioritize reliability and quality. A reliable supplier should have a proven track record of providing high-quality chemicals that meet industry standards. Researching potential suppliers involves evaluating their certifications, quality control processes, and customer reviews. Engaging with previous customers can yield insights into the supplier's consistency, delivery times, and customer service, which are vital for maintaining smooth operations in textile processing.

Additionally, consider the supplier's ability to provide a range of chemical products tailored to specific needs. A good supplier should offer technological support, including advice on the application and customization of chemicals for different textile processes. This expertise not only aids in achieving desired results but also ensures safety and compliance with regulatory guidelines. Establishing a transparent communication channel with suppliers can further enhance the partnership, enabling you to stay informed about new developments, product improvements, and any potential issues that may arise.

How to Choose the Best Textile Processing Chemicals for Your Needs

| Chemical Type | Functionality | Application Method | Environmental Impact | Supplier Reliability |

|---|---|---|---|---|

| Dyes | Coloration | Dyeing and Printing | Low impact (if sourced sustainably) | High - Verified certifications |

| Sizing Agents | Improves fabric strength | Weaving | Low to Moderate | Medium - Customer reviews checked |

| Anti-static Agents | Reduces static charge | Finishing | Moderate | High - Industry partnerships |

| Softening Agents | Enhances hand feel | Washing and Finishing | Low - Biodegradable options | Medium - Product testing available |

| Bleaching Agents | Whitening and brightness | Pre-treatment | Moderate to High | High - Compliance with regulations |

Related Posts

-

Top Textile Finishing Agents in 2025: Trends and Innovations to Watch

-

How to Capture Stunning Textile Photos That Showcase Your Fabric's Beauty

-

How to Find the Best Textile Distributors for Your Business Needs

-

Why Choosing the Right Distributor Textile Can Boost Your Business Growth by 30%

-

Top Tips for Optimizing Your Textile Website for Better Search Rankings

-

2025 How to Choose the Right Types of Textile Dyes for Your Projects