Blog

- Home

- /

- Blog

2026 How to Choose the Right Chemical Textile for Your Needs

Choosing the right chemical textile can significantly impact your projects. This decision is not always straightforward. Many factors need consideration, such as functionality, durability, and environmental impact.

Chemical textiles come in various forms. They may be used for clothing, industrial applications, or home textiles. Each category has specific needs. Choosing the wrong type can lead to performance issues. Picture a fabric that fails in moisture management during a heavy workout. It can cause discomfort and poor results.

Understanding your needs is crucial. You might initially focus on aesthetics, but the performance matters more. Think about the challenges you face. Are you prioritizing sustainability? Or do you need a durable option for harsh conditions? These factors guide your selection. Take time to reflect on what works best for you. In the end, the right choice can transform your experience with chemical textiles.

Understanding Chemical Textiles: Definition and Applications

Chemical textiles are materials treated with various chemicals to enhance their properties. These textiles are commonly used in industries that require specific performance features. For instance, they can be water-resistant, flame-retardant, or antimicrobial. Understanding these features is essential for selecting the right chemical textile for your project.

The applications of chemical textiles vary widely. In the medical field, they are used in surgical gowns and bandages that offer hygiene and protection. In the fashion industry, treated fabrics are designed to handle extreme weather conditions. However, not all chemical treatments are suitable for every application. Reflecting on the specific needs of your project is crucial. Sometimes, the most popular choice may not be the best fit. Testing the material under various conditions can reveal its true capabilities and limitations.

2026 How to Choose the Right Chemical Textile for Your Needs

| Chemical Textile Type | Definition | Applications | Benefits | Considerations |

|---|---|---|---|---|

| Flame Retardant Textiles | Fabrics treated to resist ignition and slowing down the spread of flames. | Workwear, upholstery, and curtains in public buildings. | Increased safety and compliance with fire regulations. | Can be more expensive and may require special care. |

| Waterproof Textiles | Fabrics designed to repel water and prevent dampness. | Outerwear, tents, and outdoor equipment. | Keeps users dry and enhances comfort during wet conditions. | Breathability may be compromised; can be heavier. |

| Antimicrobial Textiles | Fabrics treated to reduce the growth of bacteria, fungi, and other microbes. | Medical uniforms, sportswear, and bedding. | Helps in maintaining hygiene and reducing odor. | Efficacy may decline after numerous washes. |

| UV Protection Textiles | Fabrics designed to block harmful ultraviolet (UV) rays from sun exposure. | Outdoor apparel, swimwear, and sun protection gear. | Reduces risk of skin damage and sunburn. | May require specific washing instructions to maintain effectiveness. |

Types of Chemical Textiles: An Overview of Materials

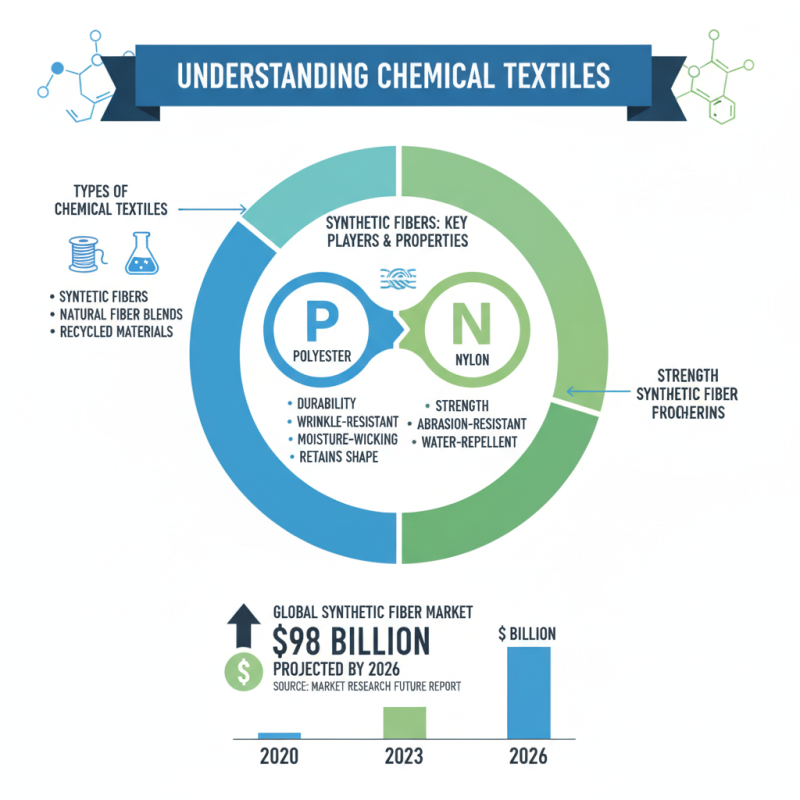

When selecting the right chemical textiles, it’s crucial to understand the various types available. Chemical textiles encompass a wide range of materials, each with unique properties. These materials include synthetic fibers, such as polyester and nylon. They are popular for their durability and resistance to moisture. According to a recent report by Market Research Future, the global market for synthetic fibers is projected to reach $98 billion by 2026.

Natural chemical textiles are also significant. Cotton treated with chemical processes can achieve enhanced durability and stain resistance. However, reliance on synthetic options raises concerns about their environmental impact. Research shows that the production of synthetic fibers can lead to a considerable amount of microplastic pollution. This aspect often goes unnoticed but warrants serious consideration.

Another material gaining traction is biopolymer textiles. Derived from renewable sources, they present an eco-friendlier alternative. However, limitations in performance and cost can hinder widespread adoption. Balancing performance and sustainability remains a key challenge in the industry. The evolving landscape of textile technology demands constant evaluation and adaptation.

Evaluating Performance: Durability, Flexibility, and Safety Factors

Choosing the right chemical textile involves understanding performance factors like durability, flexibility, and safety.

Durability is key. Textiles that wear quickly may lead to waste and added costs. You might find bright colors fade after a few washes. This can embarrass designers and users alike.

It’s important to assess how fabrics perform over time.

Flexibility is another crucial factor. Some textiles may feel stiff or uncomfortable. Users often find these materials restrict movement. This can be especially problematic in active wear or functional clothing.

On the other hand, overly flexible textiles may lack the structure needed for certain applications. Finding a balance is essential.

Safety should never be overlooked. Some textiles may contain harmful chemicals. Even subtle off-gassing can cause long-term health issues. Users may not notice problems immediately,

but reactions can develop over time. Testing for safety standards is vital, yet many overlook this step. Awareness is necessary for making informed choices.

Striking a balance among these factors can be challenging, but it’s worth the effort.

Choosing Chemical Textiles: Key Considerations for Different Industries

When choosing chemical textiles, several industry-specific considerations come into play. Different industries have unique requirements. For instance, the automotive sector demands textiles that offer durability and resistance to chemicals and heat. According to a recent report, about 25% of automotive textiles are made with advanced chemical treatments.

In the healthcare industry, cleanliness is paramount. Medical textiles must resist bacteria and withstand high-temperature sterilization. Data indicates that around 30% of healthcare textiles incorporate antimicrobial properties. This highlights the need for thoughtful selection based on application. However, many manufacturers still overlook the importance of these specifics.

Sustainability is another growing concern. The textile industry accounts for approximately 20% of global water pollution. Choosing eco-friendly chemical textiles can mitigate environmental impact. Shockingly, only about 10% of companies prioritize sustainability in their sourcing decisions. This gap suggests a need for more awareness and responsibility within the industry. Understanding these nuances can guide better choices.

Sustainability and Environmental Impact of Chemical Textiles

When selecting chemical textiles, sustainability must be considered. The production processes often use harmful chemicals that can impact ecosystems. These substances may leach into water systems, harming aquatic life. It is crucial to assess the sourcing of materials. Are they obtained responsibly?

Choosing a sustainable option can be challenging. Some fabrics might appear eco-friendly but still carry a heavy environmental footprint. Look for certifications that indicate environmental standards. However, many brands still use vague terms that need more scrutiny. Always research before making a choice.

Understanding the “why” behind your selection is vital. Are you prioritizing comfort over sustainability? Often, we overlook the larger impact. Making mindful choices can contribute to a healthier planet. Balancing quality and environmental responsibility is not easy, but it is necessary.

Related Posts

-

Top 10 Textile Chemicals and Auxiliaries You Need to Know in 2023

-

2025 Guide: How to Choose the Best Textile Fabrics for Your Projects

-

Why Are Textile Additives Essential for Improving Fabric Performance

-

Why Choosing the Right Distributor Textile Can Boost Your Business Growth by 30%

-

Top Textile Finishing Agents in 2025: Trends and Innovations to Watch

-

How to Capture Stunning Textile Photos That Showcase Your Fabric's Beauty