Blog

- Home

- /

- Blog

2025 How to Choose the Right Types of Textile Dyes for Your Projects

The selection of the appropriate types of textile dyes is a critical decision for designers and manufacturers alike, impacting both the aesthetic quality and functional performance of textile products. According to a recent market report from Grand View Research, the global textile dye market was valued at approximately $5.1 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028. This growth highlights the increasing importance of color innovation and the need for diverse dye options that meet various consumer demands and sustainability goals.

Furthermore, the diverse types of textile dyes available today—including reactive, direct, vat, and disperse dyes—each present unique properties, advantages, and limitations. For instance, reactive dyes are favored for their bright colors and good wash fastness, while vat dyes are known for their exceptional lightfastness and durability. The choice of dye can significantly affect the final product’s quality, environmental impact, and production efficiency. With an expanding focus on sustainability, many manufacturers are now seeking eco-friendly dye alternatives and processes that reduce water consumption and pollutants, reinforcing the necessity for informed decision-making when selecting types of textile dyes for various projects.

Understanding the Basics of Textile Dyeing: Types and Techniques

Understanding the basics of textile dyeing is essential for anyone embarking on a fabric-focused project. The process begins with selecting the right type of dye, which can greatly affect the final appearance and durability of the fabric. There are several categories of textile dyes, including reactive, direct, acid, and disperse dyes, each with specific uses depending on the fiber content. For instance, reactive dyes work well with cellulose fibers like cotton, resulting in vibrant and long-lasting colors, while acid dyes are ideal for protein fibers such as silk and wool, providing rich hues that are less susceptible to fading.

In addition to understanding the types of dyes, one must also consider the application techniques available. Techniques such as immersion dyeing, tie-dyeing, and batik each lend unique characteristics to the fabric. Immersion dyeing involves submerging the fabric in a dye bath for uniform color, while tie-dyeing creates patterns through folds and ties that resist dye penetration, producing beautiful contrasts. Batik, on the other hand, combines wax-resist techniques with dye on fabric to achieve intricate designs.

Choosing the right combination of dye type and technique is crucial, as it not only influences the aesthetic outcome but also the fabric's texture and washability.

The Importance of Colorfastness in Textile Dyes for Long-lasting Results

Colorfastness is a crucial factor to consider when selecting textile dyes for your projects, as it directly affects the longevity and vibrancy of the colors applied to fabrics. Essentially, colorfastness refers to a dye’s resistance to fading or running when exposed to various environmental factors such as light, washing, and abrasion. Ensuring high colorfastness means that fabrics will maintain their intended appearance over time, which is particularly important for items subjected to frequent use or exposure to the elements.

When evaluating different types of textile dyes, it is vital to understand how their chemical properties influence colorfastness. For instance, synthetic dyes typically offer superior colorfastness compared to some natural dyes, making them a popular choice for items that require durability. However, natural dyes can still achieve remarkable results when properly set with mordants or fixatives. By selecting the right dyeing technique and testing for colorfastness, textile artists and manufacturers can enhance the quality of their products and ensure customer satisfaction through vibrant, long-lasting colors.

Natural vs. Synthetic Dyes: Pros, Cons, and Environmental Impact

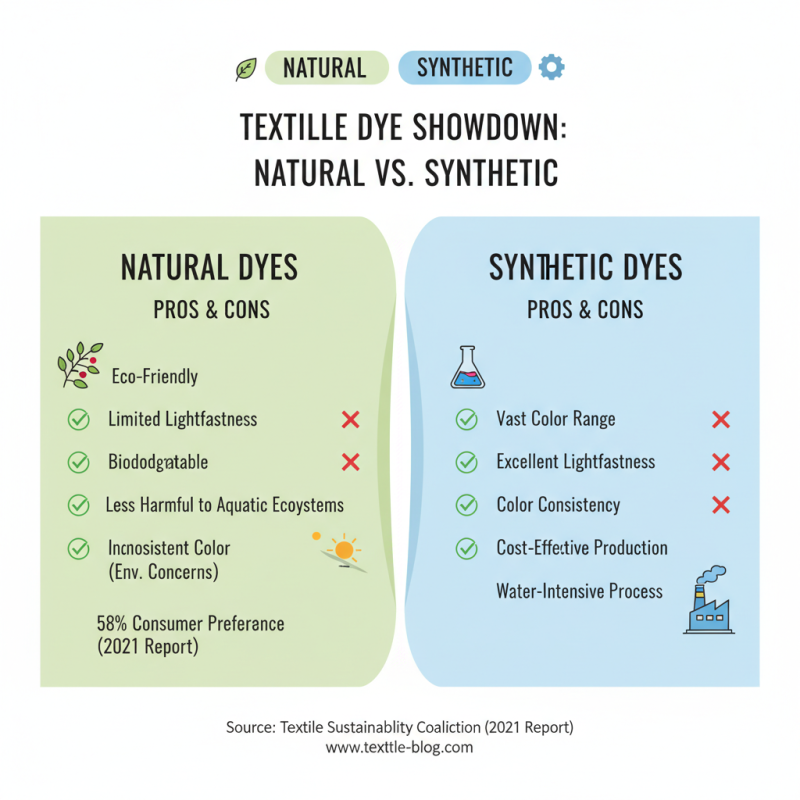

When selecting textile dyes for your projects, understanding the advantages and disadvantages of natural versus synthetic dyes is crucial. Natural dyes, derived from plant, animal, or mineral sources, are often touted for their eco-friendliness. A 2021 report from the Textile Sustainability Coalition highlights that 58% of consumers prefer eco-friendly products, thus increasing the demand for natural dyes. These dyes are biodegradable and usually less harmful to aquatic ecosystems. However, natural dyes can have limitations in terms of lightfastness and color consistency, often requiring mordants that may introduce additional environmental concerns.

On the other hand, synthetic dyes dominate the textile industry due to their versatility and vibrant color range. According to the American Association of Textile Chemists and Colorists, synthetic dyes account for approximately 80% of the global dye market, primarily due to their cost-effectiveness and stability. However, their environmental impact is significant; many synthetic dyes are derived from petrochemicals and can be toxic to aquatic life when wastewater containing residual dyes is discharged. The European Chemicals Agency warns that some synthetic dyes may also pose long-term health risks for workers involved in dye production.

Ultimately, the choice between natural and synthetic dyes should consider both the project's requirements and the broader environmental implications, aligning with consumer demand for sustainable practices in the textile industry. Understanding these factors will help you make informed decisions that benefit your projects and contribute to a more sustainable future.

Evaluating Dyeing Methods: Reactive, Acid, and Disperse Dyes Explained

When it comes to selecting the right dyeing method for your textile projects, understanding the differences between reactive, acid, and disperse dyes is crucial. Reactive dyes interact chemically with the fabric, forming strong covalent bonds that result in excellent colorfastness, particularly on cellulose fibers like cotton. According to a report by the Textile Institute, reactive dyes account for approximately 50% of the dye market due to their versatility and eco-friendliness.

Acid dyes, on the other hand, are ideal for protein fibers such as wool and silk. These dyes work well in acidic conditions, allowing for vibrant colors that can be quite brilliant. A 2022 survey from Dyeing Technologies revealed that the demand for acid dyes has surged as more designers seek high pigmentation and ease of use in natural textile production. However, it’s essential to consider water quality and pH, as they significantly impact the final color outcome.

Tip: Always test a small swatch before proceeding with your entire project. This will help you understand how the dye interacts with your specific fabric and ensure the desired results.

Disperse dyes are primarily used for synthetic fabrics, like polyester. Unlike reactive and acid dyes, disperse dyes require a heat application process, which can be more challenging but yields vibrant hues on synthetic fibers. With the rise in demand for high-performance textiles, the industry is witnessing a growth in the use of disperse dyes, with projections indicating a 6% annual increase through 2025.

Tip: When working with disperse dyes, consider the substrate's heat tolerance to avoid damaging the fabric during dyeing.

2025 How to Choose the Right Types of Textile Dyes for Your Projects

Choosing the Right Dye for Different Fabric Types: A Comprehensive Guide

Choosing the right dye for fabric types is crucial for achieving desired colorfastness and visual appeal. According to a report by Smithers Pira, the global textile dye market is expected to reach $7.93 billion by 2025, highlighting the increasing demand for specialized dyes tailored to various fabric characteristics. Different fabrics interact with dyes differently; natural fibers like cotton and wool absorb dyes distinctly compared to synthetic fibers like polyester and nylon. For example, reactive dyes are preferred for cotton due to their excellent wash fastness, while disperse dyes are more suitable for polyester because of their ability to penetrate the fiber structure effectively.

When selecting a dye, it is essential to consider not only the fabric type but also the intended use of the finished product. Ignoring the fabric’s characteristics can lead to poor performance; for instance, direct dyes can be problematic on polyester as they may not provide the necessary adhesion for vibrancy and durability. Additionally, a study by the International Journal of Clothing Science and Technology highlights the importance of conducting pre-treatment processes, as they can significantly enhance dye uptake and longevity. By understanding the compatibility between dye types and fabric materials, creators can ensure that their projects meet both aesthetic and functional requirements in textile production.

Related Posts

-

Exploring the Science Behind the 7 Major Types of Textile Dyes and Their Environmental Impact

-

10 Best Types of Dyes Used in the Textile Industry for Vibrant Fabrics

-

What are the Best Dyes for Textile Applications and Their Benefits

-

Exploring Innovations in the US Textile Industry and Their Impact on Sustainability

-

How to Find the Best Textile Distributors for Your Business Needs

-

Top 10 Textile Dyeing Chemicals You Need in Your Production Process