Blog

- Home

- /

- Blog

How to Choose the Right Textile Printing Chemicals for Your Projects?

Choosing the right textile printing chemicals is crucial for successful projects. These chemicals impact both the quality of prints and the longevity of fabrics. With so many options available, making a choice can feel overwhelming.

Consider the type of fabric you are working with. Different materials require specific textile printing chemicals to achieve optimal results. For instance, synthetic fabrics often need specialized inks. This ensures vibrant colors that adhere well and do not fade.

It's also essential to think about the printing process. Various techniques, such as screen printing or digital printing, utilize different chemical formulations. Mistakes can be costly, leading to unsatisfactory prints and wasted materials. Reflecting on past projects can help in making better decisions. By understanding the implications of your choices, you can enhance the quality of your textiles.

Understanding Various Types of Textile Printing Chemicals Available Today

When diving into textile printing, understanding the available chemicals is crucial. Different projects require different types of inks, dyes, and other substances. Water-based inks offer a more eco-friendly option. They are easy to clean up and produce less odor. However, they may not be as vibrant on certain fabrics.

Solvent-based inks, on the other hand, provide excellent color vibrancy and durability. They can work on a wider range of materials. But they often have a stronger smell and require proper ventilation during use. Many artists face challenges choosing between these two types. Each has pros and cons that can impact the final product.

Tip: Always test a small fabric sample before committing to a large batch. This step can reveal how the colors appear. It may also help identify any reactions with the fabric. Another point to consider is the drying time of the inks. Some may take longer than expected, causing delays. Reflecting on these factors can save time and frustration later.

Factors to Consider When Selecting Textile Printing Chemicals for Projects

When selecting textile printing chemicals, consider several critical factors. The type of fabric is paramount. Different textiles react uniquely to various substances. For instance, cotton responds well to water-based inks, while synthetic materials may require solvent-based options. Understanding these interactions is essential.

Another key point is the environmental impact. Sustainability is becoming increasingly vital in textile production. Look for biodegradable and non-toxic chemicals. This choice can enhance your brand image and appeal to eco-conscious consumers. Additionally, evaluate the availability of safety data sheets. This ensures that you are informed about potential hazards.

**Tips:** Test small batches before full production. This can reveal unexpected reactions. Always keep other options in mind. If one chemical doesn't work, another might. Monitor your processes closely. Improper handling can lead to unwanted effects, wasting time and resources. Your decisions should align with both quality and sustainability goals.

Textile Printing Chemicals Selection Factors

Evaluating Performance and Compatibility of Textile Printing Chemicals

Choosing the right textile printing chemicals is crucial. Evaluating their performance involves several factors. Color vibrancy, durability, and compatibility are top priorities. Understanding these elements can guide your selection process.

Testing different chemicals on various fabrics is essential. Some may work well on cotton but not on polyester. You might notice unexpected results. A dye could fade quicker than anticipated, or the print could feel rough. Monitoring how prints react to washing is equally important. This provides insight into durability.

Additionally, consider the environmental impact. Some chemicals may perform well but are harmful. Balancing performance and sustainability is challenging. Some may not fully meet eco-friendly standards. Reflecting on these discrepancies can lead to better choices in future projects.

How to Choose the Right Textile Printing Chemicals for Your Projects? - Evaluating Performance and Compatibility of Textile Printing Chemicals

| Chemical Name | Application Type | Performance Characteristics | Compatibility |

|---|---|---|---|

| Reactive Dye | Cotton and Blends | High brightness, good wash fastness | Compatible with cellulose fibers |

| Disperse Dye | Polyester | Excellent heat stability, good migration | Compatible with polyester and nylon |

| Pigment Ink | Wide Range of Substrates | Good lightfastness, eco-friendly | May require pre-treatment for some fabrics |

| Acid Dye | Wool, Silk, Nylon | Brilliant colors, excellent wash fastness | Compatible with protein-based fibers |

| Direct Dye | Cotton, Viscose | Easy application, moderate fastness | Limited compatibility with synthetics |

Sustainability and Environmental Impact of Textile Printing Chemicals

The sustainability of textile printing chemicals is a critical issue. According to the Textile Exchange, around 20% of industrial water pollution comes from textile production. Many chemicals used in this process are toxic to both human health and the environment. The need for eco-friendly alternatives is stronger than ever.

Consider the impact of azo dyes. These dyes are popular but can release harmful compounds. Studies indicate that some are carcinogenic. The World Health Organization lists them among hazardous materials. Opting for biodegradable inks can mitigate harmful effects. Reports show that water-based inks reduce volatile organic compounds (VOCs) by up to 70%.

Many companies now face scrutiny over their chemical choices. Consumers demand transparency. Sustainable production methods can drastically lower environmental footprints. A report by McKinsey found that sustainable practices can improve operational efficiency by 30%. Yet, this requires investment in research and development. The shift towards sustainability is not a quick fix; it demands commitment and continuous improvement.

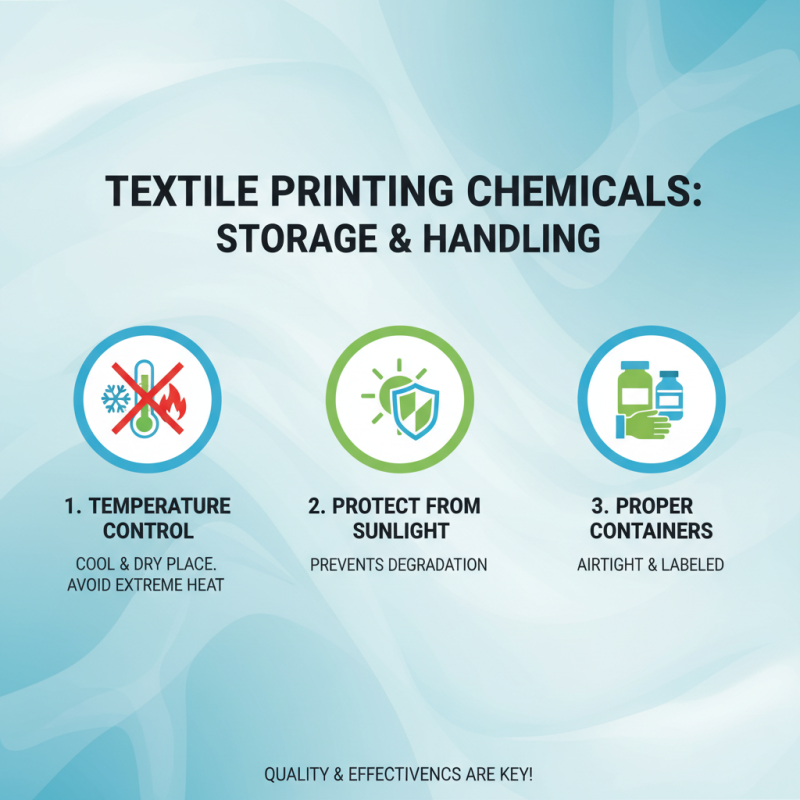

Best Practices for Storing and Handling Textile Printing Chemicals

When working with textile printing chemicals, proper storage and handling are essential. Temperature control is crucial. Ideally, keep chemicals in a cool, dry place. Extreme heat or humidity can compromise the quality of the chemicals. Sunlight also degrades many printing substances, making them less effective over time.

Always label containers clearly. This helps prevent mix-ups and ensures safety during use. Use airtight containers to avoid exposure to air and moisture. Consider creating an inventory list. This will help track expiration dates and minimize waste.

Tips: Use gloves and goggles when handling chemicals. Even small spills can be harmful. Regularly check stock levels, and dispose of expired chemicals responsibly. Safety must come first, but complacency often leads to accidents. Be vigilant and cautious.

Related Posts

-

2025 How to Choose the Right Types of Textile Dyes for Your Projects

-

Top Tips for Optimizing Your Textile Website for Better Search Rankings

-

How to Capture Stunning Textile Photos That Showcase Your Fabric's Beauty

-

What is Textile Colouring and How Does it Impact Fabric Quality and Design

-

Top 10 Textile Dyeing Chemicals You Need in Your Production Process

-

Top 10 Textile Chemicals and Auxiliaries You Need to Know in 2023