Blog

- Home

- /

- Blog

2025 How to Choose the Right Types of Textile Dyes for Your Projects

In the world of textile manufacturing, selecting the appropriate types of textile dyes is crucial for achieving the desired aesthetic and functional qualities in fabric products. As the global textile dye market is projected to reach USD 6.2 billion by 2025, it is essential for designers and manufacturers to make informed choices about the dyeing processes they implement. A recent report by the American Association of Textile Chemists and Colorists emphasizes that “the right dye selection can enhance fabric performance and sustainability,” indicating that the implications of this choice extend beyond mere color.

According to industry expert Dr. Emily Carter, a renowned figure in textile chemistry, “Understanding the properties and compatibility of various types of textile dyes can lead to significant improvements in durability and colorfastness.” With an ever-growing emphasis on eco-conscious practices, selecting the right dye not only reflects a commitment to quality but also to environmental sustainability. As projects become more ambitious in terms of color richness and fabric innovation, the demand for knowledgeable insights into the diverse types of textile dyes available has never been more significant. This guide aims to provide a comprehensive overview to facilitate informed decision-making for those navigating this complex landscape.

Understanding the Different Types of Textile Dyes Available

When choosing the right types of textile dyes for your projects, understanding the various options available is crucial. Textile dyes can be classified into several categories based on their chemical composition, application methods, and the types of fabrics they effectively color. According to the Global Textile Dyes Market report, the demand for reactive dyes has been on the rise due to their excellent quality and versatility, particularly for cotton and other cellulosic fibers. These dyes form a covalent bond with the fiber, resulting in vibrant colors and exceptional wash fastness, making them a popular choice for both commercial and DIY textile projects.

In contrast, acid dyes are primarily used for protein fibers like wool and silk. They offer brilliant hues and a wide application range but require careful handling due to their sensitivity to pH levels. On the other hand, disperse dyes are specifically formulated for synthetic fibers such as polyester, allowing for high-color buildup and shade depth. The world textile dye market is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2020 to 2027, indicating an increasing interest in sustainable and innovative dyeing techniques. Knowing the characteristics and suitable applications of these different dye types enables you to make informed decisions that align with your project goals, ensuring both aesthetic appeal and functional performance in your textile crafts.

2025 Textile Dyes Comparison

This chart illustrates the distribution of different types of textile dyes based on their popularity and application in various textile projects. The data reflects the increasing interest in environmentally friendly and synthetic dyes as of 2025.

Factors to Consider When Selecting Textile Dyes for Your Project

When selecting textile dyes for your project, several crucial factors must be taken into account to ensure the best results. First and foremost, consider the type of fabric you will be dyeing. Different fibers interact uniquely with various dye types; for example, natural fibers like cotton and wool often require distinct dyes, such as fiber-reactive or acid dyes, respectively. Additionally, the dye's ability to bond with the fabric can significantly affect the vibrancy and longevity of the color.

Another important factor is the dye's environmental impact and safety. Many dyes are now available in eco-friendly formulations that minimize harm to both the user and the environment. It's essential to evaluate whether the dyes meet safety standards and consider using non-toxic options, especially if the textiles will be worn close to the skin or used in children’s products. Additionally, consider the dyeing process itself; some dyes require specific techniques or binds, which might affect your chosen method of application. Understanding these variables will help you make an informed decision that aligns with your project’s goals and values.

Analyzing the Compatibility of Dyes with Various Fabrics

When selecting textile dyes for your projects, understanding the compatibility of dyes with various fabrics is crucial to achieving the desired results. Different types of fabrics, such as natural fibers (like cotton and silk) and synthetic fibers (like polyester and nylon), react uniquely to various dyes due to their distinct chemical compositions. For instance, natural fibers typically bond well with reactive and fiber-reactive dyes, while synthetic fibers require disperse dyes for optimal results. According to the Textile Industry Annual Report, properly matching dye types to fabric can enhance colorfastness and garment longevity by up to 30%.

Tips: Always conduct a small test swatch before proceeding with larger dyeing projects. This helps to gauge the final color and compatibility of the dye with the fabric, reducing the risk of unexpected results.

Additionally, some dyes may require specific application techniques or chemical additives to achieve the best outcome. While acid dyes are perfect for protein fibers like wool, a different methodology is needed for cellulose fibers. The Textile Research Journal reports that projects that utilize proper dye and fabric combinations report a 25% higher satisfaction rate among consumers, emphasizing the importance of informed dye selection.

Tips: Research the dyeing method that best suits your fabric type, whether it’s immersion, tie-dye, or batik, to ensure vibrant and lasting colors.

2025 How to Choose the Right Types of Textile Dyes for Your Projects - Analyzing the Compatibility of Dyes with Various Fabrics

| Fabric Type | Recommended Dye Type | Application Method | Colorfastness | Compatibility Notes |

|---|---|---|---|---|

| Cotton | Reactive Dyes | Machine Dyeing | Excellent | Requires pre-treatment |

| Silk | Acid Dyes | Hand Dyeing | Good | Requires vinegar for fixation |

| Wool | Acid Dyes | Steaming | Very Good | Sensitive to heat |

| Polyester | Disperse Dyes | High-Temperature Dyeing | Good | Requires specific temperature |

| Nylon | Acid Dyes | Machine Dyeing | Good | Keep pH neutral |

Exploring the Application Methods for Textile Dyes

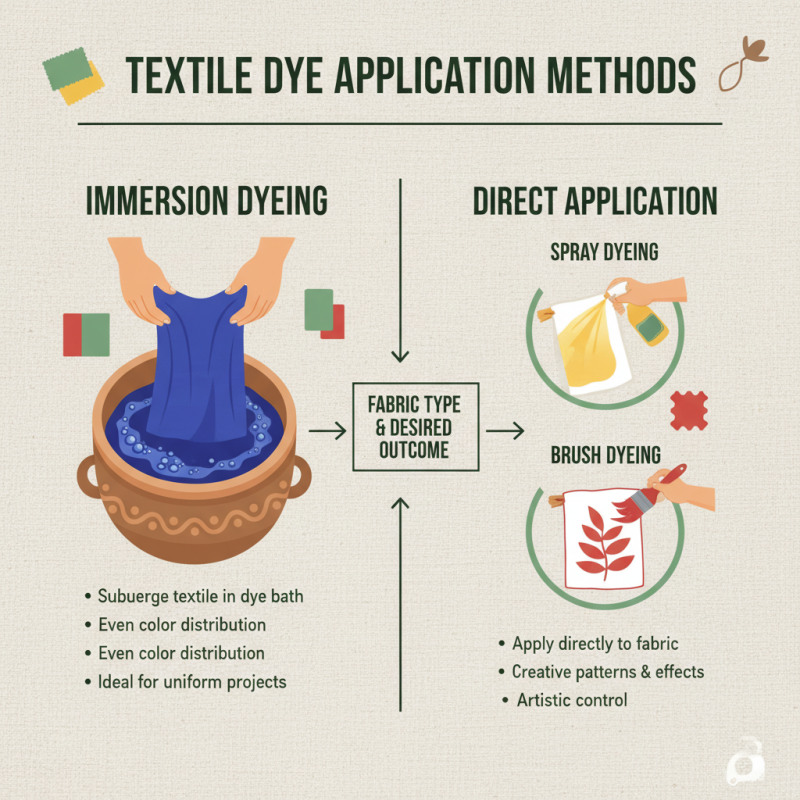

When exploring the application methods for textile dyes, it becomes essential to consider the fabric type and the desired outcome. The most common dye application methods include immersion dyeing, where textiles are submerged in a dye bath, and direct application techniques such as spray or brush dyeing. Immersion dyeing is versatile and can achieve an even distribution of color, making it ideal for projects requiring uniformity. Meanwhile, spray and brush techniques allow for more creative control, enabling artisans to create patterns and effects directly on the fabric.

In addition to traditional methods, modern technologies such as digital printing and reactive dyeing have emerged, providing new dimensions in textile design. Digital printing allows for intricate designs and the application of multiple colors without the risk of bleeding, while reactive dyes bond chemically with the fabric, resulting in vibrant colors that are also washfast. Choosing the right method not only influences the final appearance of the textile but also affects the fabric's feel and durability, underscoring the importance of selecting the most suitable application technique for your specific project needs.

Evaluating the Environmental Impact of Textile Dye Choices

When selecting textile dyes for projects, it is imperative to consider their environmental impact due to the substantial pollution associated with dye production and application. According to a report by the United Nations Environment Programme, textile dyeing is responsible for approximately 20% of global industrial water pollution, exceeding the toxic load produced by many other industries. This phenomenon is primarily caused by the release of hazardous chemicals, such as heavy metals and organic solvents, into water bodies, which can lead to ecological damage and health risks for local communities.

One method of mitigating these environmental concerns is to opt for dyes that are derived from natural sources or have been certified as “eco-friendly.” A study by the Textile Exchange revealed that the demand for organic and sustainable fibers is increasing, with a reported 25% rise in the use of organic cotton in recent years. Natural dyes, such as those derived from plants, can significantly reduce the ecological footprint of textile manufacturing, as they often require fewer chemicals for fixation and less water during processing. Additionally, the adoption of modern dyeing technologies, such as waterless dyeing systems, is becoming more prevalent, showing a decrease in water consumption by up to 90% compared to traditional methods.

By carefully evaluating the environmental impact of dye choices, textile producers and consumers can play a critical role in fostering a more sustainable industry. By prioritizing eco-friendly alternatives and innovative technologies, the sector can contribute to pollution reduction and conservation efforts, ultimately leading to a healthier planet for future generations.

Related Posts

-

Exploring the Science Behind the 7 Major Types of Textile Dyes and Their Environmental Impact

-

2025 How to Choose the Right Types of Textile Dyes for Your Projects

-

2025 Top 10 Types of Dyes Revolutionizing the Textile Industry

-

10 Best Types of Dyes Used in the Textile Industry for Vibrant Fabrics

-

What are the Best Dyes for Textile Applications and Their Benefits

-

Top Tips for Optimizing Your Textile Website for Better Search Rankings