Blog

- Home

- /

- Blog

Comprehensive Guide to Textile Dyeing Chemicals List for Professionals

The textile dyeing industry plays a crucial role in the overall fabric manufacturing process, and understanding the various chemicals involved is essential for professionals seeking to optimize their operations. A comprehensive textile dyeing chemicals list not only provides insight into the specific substances used but also highlights their applications, safety considerations, and environmental impacts, making it a vital resource for sustainable production practices. According to a recent report by the International Textile Manufacturers Federation, the global textile dyeing market is expected to grow at a CAGR of 4.5% from 2022 to 2027, emphasizing the increasing importance of efficient and responsible dyeing practices.

As experts like Dr. Angela Trombetta, a leading researcher in textile chemistry, assert, "Knowledge of dyeing chemicals is key to mastering the art of textile production and sustainability." Her assertion underscores the necessity for industry professionals to equip themselves with comprehensive knowledge about the textile dyeing chemicals list and their functionalities. This guide aims to serve as a fundamental resource for professionals in the textile sector, facilitating informed decision-making and promoting best practices across the dyeing process. Through detailed exploration of various chemicals, their risks, and their applications, this guide seeks to enhance both the proficiency and responsibility of practitioners in the textile dyeing domain.

Overview of Textile Dyeing Chemicals: Types and Applications

Textile dyeing chemicals play a crucial role in the fabric production industry, enabling professionals to achieve the desired colors and effects on various textiles. These chemicals can be broadly categorized into several types, including direct dyes, reactive dyes, vat dyes, and acid dyes. Each type serves a specific purpose depending on the fabric being dyed. For example, reactive dyes are favored for their vibrant colors and strong bonding with cellulose fibers, making them suitable for cotton and other plant-based textiles. Conversely, acid dyes are often used for protein-based fibers like silk and wool due to their ability to produce rich hues.

In addition to these primary categories, textile dyeing chemicals also include auxiliaries that enhance the dyeing process. These auxiliaries, such as surfactants, leveling agents, and fixatives, play a significant role in improving the dyeing efficiency and ensuring uniform color distribution. Surfactants help in reducing surface tension, allowing dyes to penetrate fabric more easily, while leveling agents work to achieve an even dye uptake. Fixatives, on the other hand, are essential in promoting the permanence of the color on the textile, ensuring that the dyed fabric withstands washing and wear over time. Understanding these various types and their applications is essential for professionals in the textile industry to achieve high-quality dyeing results.

Essential Dyes and Pigments: Characteristics and Usage in Textiles

In the textile industry, the choice of dyes and pigments significantly affects both the visual appeal and functional qualities of fabrics. One of the key parameters to consider is the color fastness of the dye, which determines how well the color withstands washing, light, and other environmental factors. According to the "Textile Dyes Market Report" published by Mordor Intelligence, reactive dyes, which exhibit excellent dye fixation and wash fastness, are gaining popularity in cotton and other cellulose-based fabrics. Their ability to chemically bond with fibers makes them ideal for high-quality textile applications.

Additionally, pigment-based dyeing offers distinct advantages in terms of versatility and environmental safety. Unlike traditional dyeing methods that often rely on water-intensive processes, pigments can be applied in a more sustainable manner, using less water and energy. Reports indicate that the market for organic pigments is expected to see a compound annual growth rate (CAGR) of 5.8% over the next five years, driven by the rising demand for environmentally friendly textiles. This shift not only enhances the sustainability of the textile industry but also meets consumer preferences for eco-conscious products.

Understanding the characteristics and appropriate applications of these essential dyes and pigments is crucial for professionals in the textile field, ensuring their designs are both vibrant and enduring while meeting modern sustainability standards.

Chemical Agents in Dyeing: Role of Auxiliaries and Additives

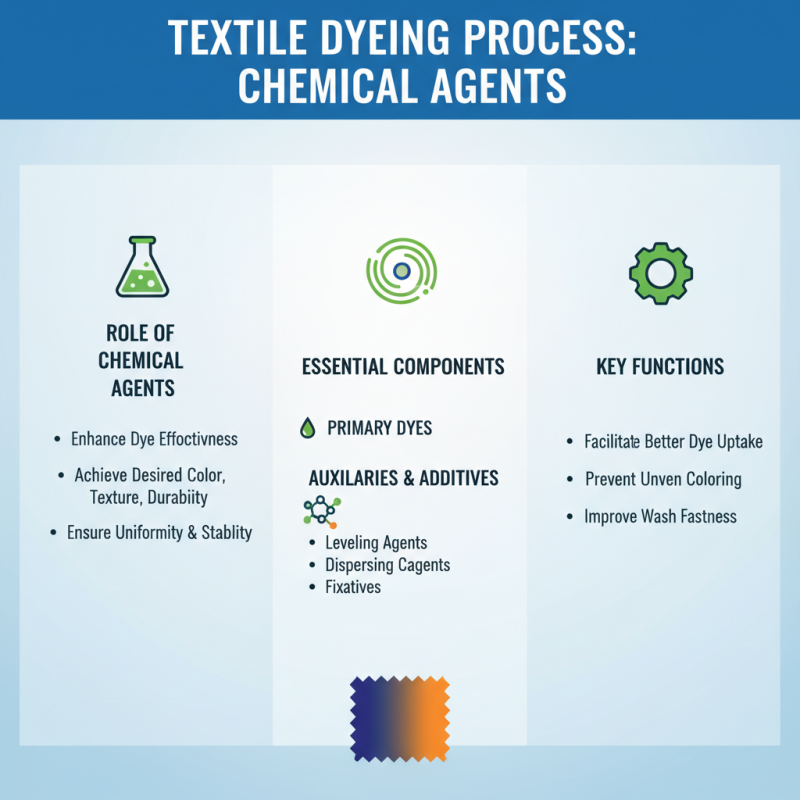

In the textile dyeing process, chemical agents play a crucial role in achieving the desired color, texture, and durability of fabrics. Auxiliaries and additives are essential components that enhance the effectiveness of primary dyes, ensuring uniformity and stability in the dyeing process. These agents can include leveling agents, dispersing agents, and fixatives, each serving specific functions that facilitate better dye uptake and prevent issues such as uneven coloring or wash fastness.

Leveling agents help to control the rate at which dye molecules are absorbed into the fiber, allowing for a more even coloration. This is particularly important when working with varied fabric types or dye materials. Meanwhile, dispersing agents aid in the distribution of dye particles in the dyeing bath, preventing agglomeration and ensuring a consistent application across the fabric surface. Fixatives, on the other hand, are added post-dyeing to enhance the bond between the dye and the fiber, improving the longevity of the color and its resistance to fading over time.

Ultimately, the judicious use of these auxiliaries and additives not only optimizes the dyeing process but also elevates the quality of the finished textile products. This understanding of their roles allows professionals in the industry to select and utilize chemical agents that best meet the needs of their specific projects, resulting in high-quality dyed textiles that maintain their aesthetic appeal and functionality throughout their lifespan.

Environmental Impact: Regulations and Sustainable Practices in Dyeing

The environmental impact of textile dyeing is a significant concern for the industry, as traditional dyeing processes often result in the release of harmful chemicals and waste into waterways. To mitigate these effects, regulations have been established worldwide, mandating the treatment of effluents and the responsible use of dyes. Professionals in the field must stay informed about these regulations, as they can influence production practices and supply chain choices. Sustainable practices, such as the adoption of natural dyes and closed-loop systems that recycle water and chemicals, are gaining traction as viable solutions.

Tips: When selecting dyeing chemicals, consider those that are certified eco-friendly and have minimal environmental impact. Implementing a waste management strategy that includes recycling and proper disposal of dye baths can significantly reduce the ecological footprint.

Moreover, professionals should prioritize transparency in their sourcing and production processes. Collaborating with suppliers who adhere to sustainability standards can enhance brand credibility and appeal to environmentally conscious consumers. Training staff on sustainable dyeing techniques also plays a crucial role in fostering a culture of environmental responsibility within organizations. By adopting these sustainable practices, the textile industry can work towards reducing its overall ecological footprint while maintaining high-quality standards in dyeing.

Textile Dyeing Chemicals Environmental Impact: Quantitative Analysis

Safety Protocols: Handling and Risk Management of Dyeing Chemicals

Handling dyeing chemicals in the textile industry requires stringent adherence to safety protocols to ensure the well-being of professionals and the environment. One of the primary steps in risk management is to conduct thorough risk assessments before using any chemical. This involves identifying potential hazards associated with each dyeing agent, understanding their chemical properties, and evaluating exposure routes. Proper ventilation in workspaces is essential to mitigate inhalation risks, while personal protective equipment (PPE) such as gloves, goggles, and respirators can significantly reduce the chances of skin and eye contact.

Furthermore, maintaining proper storage and labeling practices is crucial for safety. Chemicals should be stored in clearly labeled containers, indicating their contents and potential hazards. Access to first-aid kits and spill containment materials should be readily available for immediate response in case of an accident. Regular training sessions for staff on the safe handling and emergency response related to dyeing chemicals enhance awareness and preparedness, ensuring that employees are equipped to manage risks proactively. Implementing these safety protocols not only protects workers but also fosters a culture of safety within the industry.

Related Posts

-

Top 10 Textile Dyeing Chemicals You Need in Your Production Process

-

What is Textile Colouring and How Does it Impact Fabric Quality and Design

-

Exploring the Science Behind the 7 Major Types of Textile Dyes and Their Environmental Impact

-

2025 Top 10 Textile Auxiliaries Innovations Driving Sustainability and Efficiency

-

2025 Top 10 Types of Dyes Revolutionizing the Textile Industry

-

10 Best Types of Dyes Used in the Textile Industry for Vibrant Fabrics