Wet rubbing fastness is the foundation of textile finishing, where fabrics maintain their color and quality when wet rubbing.

Its importance, testing methods, influences and advanced textile finishing chemicals that improve performance are discussed in this article.

Everything from apparel to upholstery will be explored regarding how functional finishes for textiles prevent color bleeding.

Find out how Colourinn Auxiliaries provides sustainable solutions for superior textile finishing.

Overview: Wet Rubbing Fastness

- Definition: Wet rubbing fastness measures a fabric’s ability to resist color transfer during wet friction, crucial for textile finishing.

- Importance: Avoids color bleeding in wet conditions; improves durability and aesthetics of fabric.

- Testing: Uses a crockmeter and wet rubbing cloth to grade dye transfer 1-5.

- Factors: Dye type, fabric structure and textile finishing chemicals affect performance.

- Solutions: Fixatives, silicone softeners & resin-based finishes improve wet rubbing fastness.

- Sustainability: Eco-friendly functional finishes for textiles have less environmental impact.

Why Wet Rubbing Fastness Matters

Fastness of wet rubbing is an important quality control in textile finishing to ensure color retention and quality under wet friction. The importance lies in both functionality and consumer trust:

- Color bleeding prevents staining of adjacent fabrics during washing or rain exposure.

- Improves fabric durability and appearance with repeated use.

- Brings consumer satisfaction by supplying durable textiles.

- Supports brand rep – fewer returns due to fading/staining.

- Allows compliance with world textile finishing standards, enabling market competitiveness.

- Product longevity is critical for apparel, upholstery and technical textiles.

- Meets customer expectations for high-quality fabric finishing.

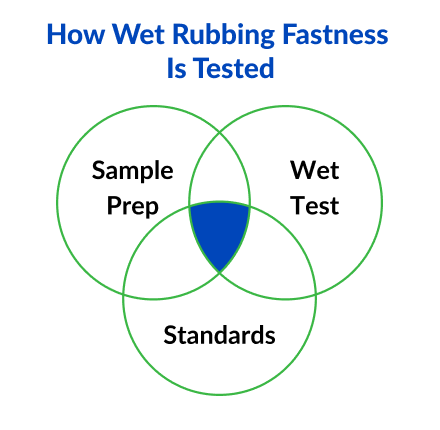

How Wet Rubbing Fastness Is Tested

Testing wet rubbing fastness uses standardised methods of color transfer evaluation. The most common is a crockmeter, which presses a damp white cotton cloth against a sample of fabric. Gradient of color transfer on a Grey Scale of Staining, 1 (high color transfer) to 5 (no transfer). Key aspects include:

- Wet Test: A rubbing cloth with 65-100% wet pickup simulates real-world wet conditions.

- Standards: ISO 105-X12 & AATCC 8 are the most common, with slight differences in wet pickup.

- Sample Prep: Fabrics are tested post-dyeing/finishing for processing effects.

A 3-4 grade is generally OK for wet rubbing, although darker colors get lower scores because of higher dye loads.

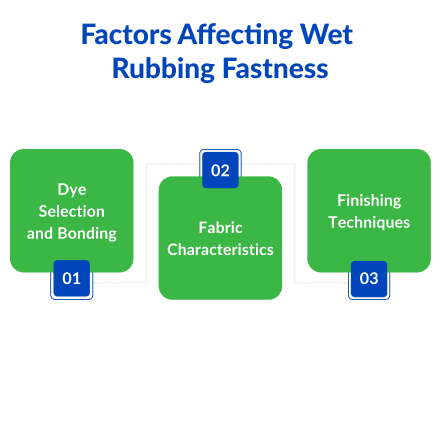

Factors Affecting Wet Rubbing Fastness

Wet rubbing fastness is influenced by a number of factors in textile finishing which affect the binding of dyes with fibers. Knowing these helps manufacturers optimize fabric finishing processes.

- Dye Selection and Bonding

Reactive and direct dyes, found in cellulose fibres, often have water-soluble groups that dissolve in wet rubbing and reduce fastness. A good dye choice and fixation treatment reduce this risk. A major cause of color transfer is unfixed “floating” dyes.

- Fabric Characteristics

Fabric structure and fibre type are important. As an example, short fibre cotton or rough cotton fabrics will abrade and transfer color when rubbed wet. Using combed or mercerised cotton improves fastness by removing loose fibres.

- Finishing Techniques

Finishing chemicals such as fixatives and silicone softeners increase wet rubbing fastness. Silicone softeners act as a protective layer to reduce friction, and cationic fixatives strengthen dye-fibre bonds.

Enhancing Wet Rubbing Fastness

Optimal use of finishing chemicals and processes is required to improve wet rubbing fastness. Here are key approaches:

- Pre-Treatment: Proper pre-treatment (scouring, desizing, mercerising) puts fabrics in the proper state to receive a dye by removing impurities and/or flattening out surfaces. Mercerizing cotton reduces fibre protrusion up to 30%.

- Fixative Agents: Cationic fixatives attach themselves electrostatically to anionic dyes in fibres. Crosslinking agents form covalent bonds, reducing dye migration further. These are essential for reactive and direct dye.

- Silicone Softeners: Silicone functional finishes for textiles are hydrophobic layers that reduce friction and dye loss with wet rubbing. Macro emulsions of silicone softeners are particularly effective for surface smoothness.

- Resin-Based Finishes: Resin finishes form a barrier to pigment detachment in printed fabrics. Durability requires proper curing.

- Eco-Friendly Solutions: More eco-friendly finishing chemicals: biodegradable fixatives & silicone emulsions improve wet rubbing fastness.

Applications in Textile Industries

- Apparel: Color transfer in jeans, activewear & dresses is prevented when washing/sweating.

- Home Textiles: Keeps towels, bed linens, and curtains looking bright after multiple washes.

- Upholstery: It makes furniture fabrics resistant to moisture and friction.

- Technical Textiles: Medical fabrics, outdoor gear, and automotive textiles are supported reliably.

- Fashion Industry: Functional finishes for textiles make for better premium garments.

- Hospitality Sector: Makes sure linens in hotels are quality maintained after frequent laundering.

- Sportswear: Uses finishing chemicals to retain color in high-friction environments.

Challenges in Achieving High Wet Rubbing Fastness

Obtaining robust wet rubbing fastness in textile finishing faces several challenges:

- Dark Colors: High dye loads cause color transfer risk in deep shades.

- Fabric Structure: Wet rubbing fastness is decreased on lightweight or fuzzy fabrics.

- Environmental Impact: Traditionally applied textile finishing chemicals may harm ecosystems.

- Sustainability Needs: Textile eco-friendly functional finishes need to be reapplied frequently.

Colourinn’s Commitment to Superior Wet Rubbing Fastness

Wet rubbing fastness is a priority at Colourinn Auxiliaries for textiles that are colorfast and durable.

This guide has reviewed its importance, testing methods, and advanced textile finishing chemicals like fixatives and silicone softeners, enhancing fabric finishing.

Our solutions ensure fabrics resist wet friction while meeting industry standards and consumer demands.

Want to make your textiles stand out with functional finishes for textiles of the very highest calibre?

Explore new textile finishing chemicals from Colourinn Auxiliaries. Learn how we can help you create vibrant fabrics that last.

Frequently Asked Questions(FAQs):

Q1. What is wet rubbing fastness in textiles?

A. Wet rubbing fastness refers to a fabric’s resistance to color transfer when rubbed while wet. It is a key quality parameter in textile finishing, ensuring that dyes do not bleed or fade during washing, sweating, or rain exposure.

Q2. Why is wet rubbing fastness important in textile finishing?

A. It helps maintain the color integrity of fabrics, improves product durability, and enhances consumer satisfaction. Strong, wet rubbing fastness reduces staining of other garments and minimizes returns or complaints.

Q3. How is wet rubbing fastness tested?

A. Wet rubbing fastness is tested using a crockmeter, where a damp white cloth is rubbed against a fabric sample. The degree of color transfer is rated on a scale from 1 (poor) to 5 (excellent), using ISO 105-X12 or AATCC 8 standards.